|

Application scope of circular permanent magnet chuck: lathe, grinder rotary processing, marking, etc.

Main technical parameters of circular permanent magnet chuck: (1) suction > 80N/cm²(2) remanence < 10% of suction at corresponding points

Minimum and maximum specifications of circular permanent magnet chucks:

Minimum Specification: Diameter 100 Maximum Specification: Diameter 600

Method of using circular permanent magnet chuck:

1. Place the workpiece on the table of the sucker, then insert the wrench into the hole of the shaft and rotate 180 to ON clockwise, so that the workpiece can be absorbed for processing.

2. After the workpiece is processed, the workpiece can be removed by inserting the wrench into the shaft hole and turning 180 to OFF counter-clockwise.

Maintenance and maintenance of round permanent magnet chuck:

1. Before using the sucker, the surface should be cleaned to avoid scratching affecting the accuracy.

2. Use the ambient temperature at - 40C-50C. Strike is strictly prohibited to prevent magnetic force from decreasing.

3. Coat the working face with anti-rust oil after use to prevent rust.

|

|

Circular permanent magnet chuck |

|

|

|

Circular permanent magnet chuck | |

Product performance: Round permanent magnet chuck is suitable for grinding machine, lathe, benchmarking and other suction workpiece processing.

Product features:

(1) It can be installed in rotary grinding machine.

(2) It is suitable for precision grinding of small and thin workpieces.

(3) Low residual magnetism.

(4) It can improve grinding of thin workpieces.

(5) It can adjust magnetic strength appropriately.

|

206 |

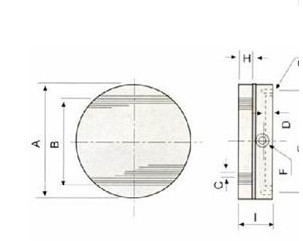

model |

size |

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

206-1 |

Xm51-125 |

125 |

80 |

2.5(1+1.5) |

2 |

112 |

10 |

M6 |

20 |

58 |

|

206-2 |

Xm51-160 |

160 |

115 |

2.5(1+1.5) |

2 |

140 |

10 |

M8 |

20 |

58 |

|

206-3 |

Xm51-200 |

200 |

155 |

2.5(1+1.5) |

2 |

180 |

10 |

M10 |

20 |

58 |

|

206-4 |

Xm51-250 |

250 |

205 |

2.5(1+1.5) |

2 |

224 |

10 |

M10 |

20 |

58 |

|

206-5 |

Xm51-300 |

300 |

255 |

2.5(1+1.5) |

2 |

260 |

10 |

M10 |

20 |

58 |

|

206-6 |

Xm51-400 |

400 |

355 |

2.5(1+1.5) |

2 |

350 |

10 |

M10 |

20 |

58 |

|

206-7 |

Xm51-500 |

500 |

455 |

2.5(1+1.5) |

2 |

440 |

10 |

M12 |

20 |

58 |

|

206-8 |

Xm51-600 |

600 |

555 |

2.5(1+1.5) |

2 |

550 |

10 |

M12 |

20 |

58 |

Suggestions for use: There are two ways of installation (through hole/block). Please choose products according to the way of installation.

More specifications can be customized. |