|

Magnetic template

The magnetic template is made of whole steel plate processed on special CNC, which is more compact, rigid and firm.

A special imported epoxy resin magnetic coil and magnet with high temperature and dynamic resistance are used to seal the magnetic template. The sealing height is slightly lower than the surface of the magnetic pole to avoid air gap between the mould and the magnetic template when the temperature rises too high.

Fixed holes and die ejection holes for mounting and moving die-side are drilled on the magnetic template, and positioning rings are equipped for rapid positioning of the die.

The junction box of the magnetic template is arranged in the interior to avoid damage, and has the characteristics of waterproof and high impedance.

The rectangular steel plate expands to a large area around the magnetic pole, which can increase the contact area between the magnetic template and the die, and make the fixing of the die more stable.

Induction switch

An induction switch is installed in the neutral area of the magnetic template to detect the contact state of the mould, so as to ensure the normal operation of the injection moulding machine and punch press and the safety of the operator.

Electronic control unit

The electronic control unit is designed according to the latest international standards. It has a flexible and diverse interface and is suitable for any old and new injection moulding machines and punching machines. It is the perfect embodiment of high technology. All control and operation functions can be easily realized by remote controller. Mould installation staff can safely stand outside the injection moulding machine and punch to carry out all the operation of mould installation.

Three-stage safety device

The operating system can only be turned on through three-level security protection devices, which further ensures the security performance.

Electromagnetic sensor

Electromagnetic sensor detects magnetic saturation intensity through some magnetic poles, and the detection is normal. Only injection moulding machine and punch can work.

Standard configuration

Electronic control unit of magnetic fixed template and magnetic dynamic template with central positioning ring, injection hole and ejection hole, IP54 electronic control box, with PLC interface, magnetization/demagnetization button, signal lamp, remote controller micro switch, magnetization/demagnetization cable of magnetic detection sensor, power supply cable and fixed screw instructions matched with connection plug

Technical Parameters of Steel Electronically Controlled Permanent Magnet Template

Power Supply

Three-phase AC380V + 10%

Magnetizing output time

0.1 ~ 0.9S

Adjustable silicon conduction angle

0-180 degree adjustable

Output current per circuit

Less than DC60A

Pole size

47X47, 70X70;

Nominal suction

7kgf/cm2--18kgf/cm2

Conditions of use

1. Ambient temperature: - 10 1 + 40 C;

2. Relative humidity: <90%(20 C):

3. Environment: There should be no conductive dust, explosive, flammable and corrosive gases in the place of use.

4. The range of input voltage fluctuation is within (±10%).

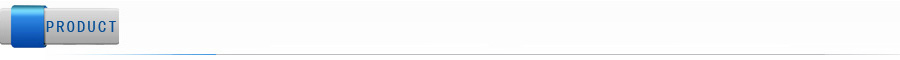

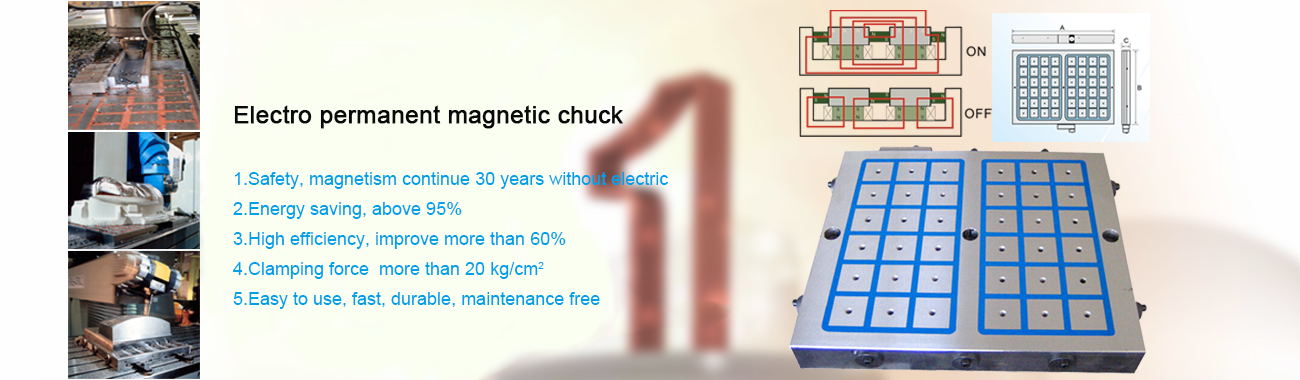

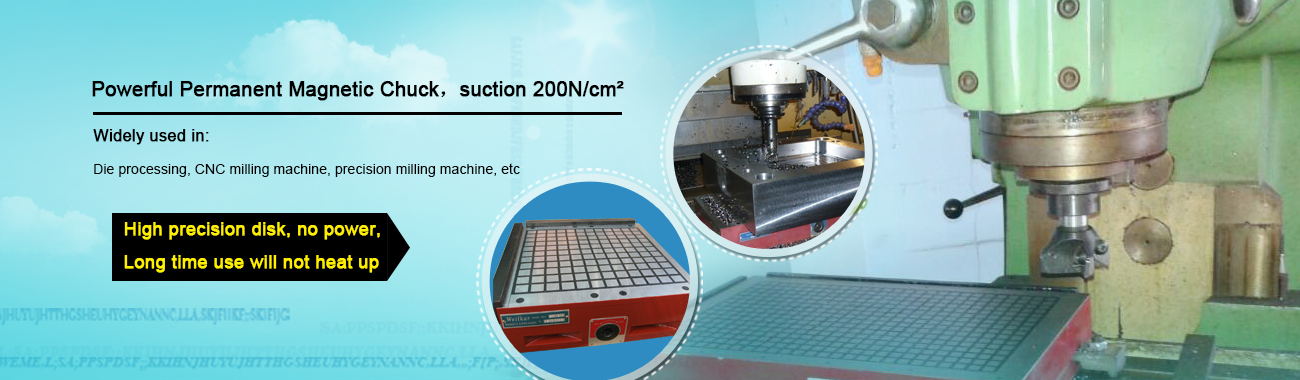

Brief Introduction to the Function of Electric Permanent Magnet Sucker

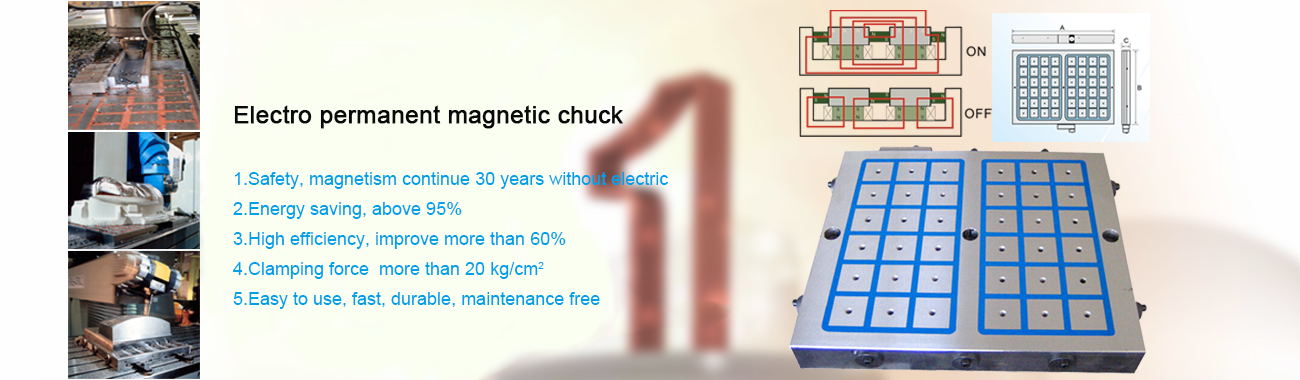

Electric permanent magnet chuck is an alternative product after permanent magnet chuck and electromagnetic chuck. It is one of the most advanced magnetic clamping products in the magnetic industry at home and abroad.

The main characteristics of the electro-permanent magnet system are as follows:

The magnetic force is strong and the processing precision is high. The maximum suction of the table can reach 18 kg/cm_, which is about 2 times that of the ordinary magnetic suction cup. It ensures that the workpiece clamping is firm and does not appear scratch and pull. Because the power supply is not needed during the processing, there is no thermal deformation in the product, which effectively guarantees the processing accuracy.

Safety, strong, energy saving, environmental protection. Electric permanent magnet suction cup does not need electric energy in the working process, but only relies on permanent magnet suction to hold the workpiece, which avoids the danger that the workpiece will fall off due to sudden power failure and off-line damage of the electromagnetic system. Because the electric permanent magnet chuck only uses electric energy within 1-2 seconds of the process of magnetization and demagnetization, it is not suitable for any energy to produce safe, strong and efficient power, which is economical and environmentally friendly.

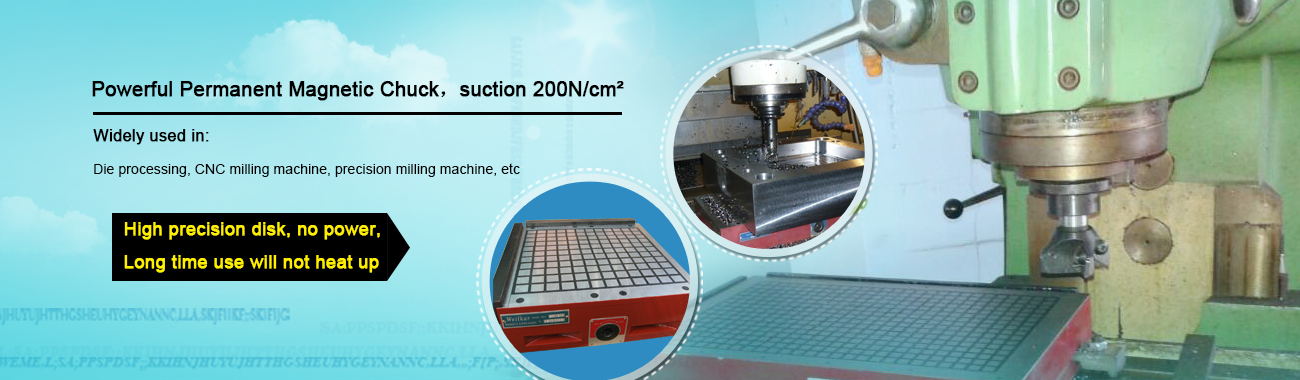

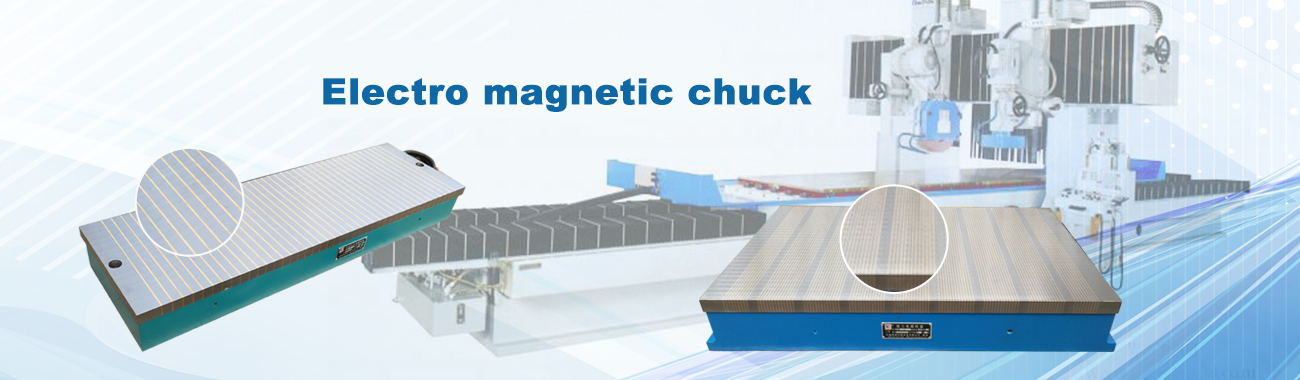

Applications:CNC Machine Tools and Machining Center: Chess Lattice and Bar Electric Permanent Magnet Sucker.

Processing guideway: super power electro-permanent magnet chuck.

Lathe disc parts: Permanent magnet sucker for vehicle use.

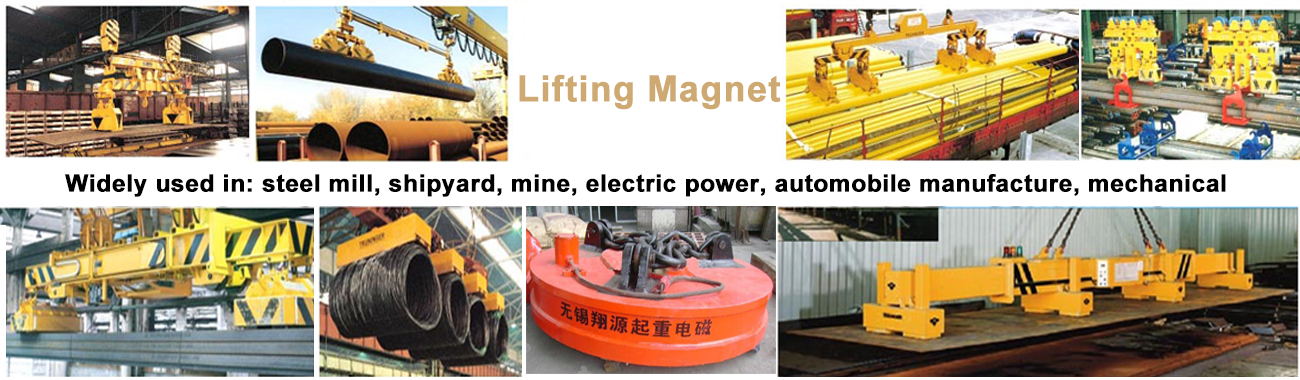

Feeding for large steel plate handling and cutting machine: heavy, medium and light hoisting electric permanent magnet hoist.

Grabbing machinery of automobile and ship industry and automatic line of various production lines: small and miniature electric permanent magnet crane.

The company has also recently developed and manufactured grinder permanent magnet chucks and spark permanent magnet chucks, each product is dozens of specifications for customers to choose, and according to customer needs, can customize different specifications, different models of products. |